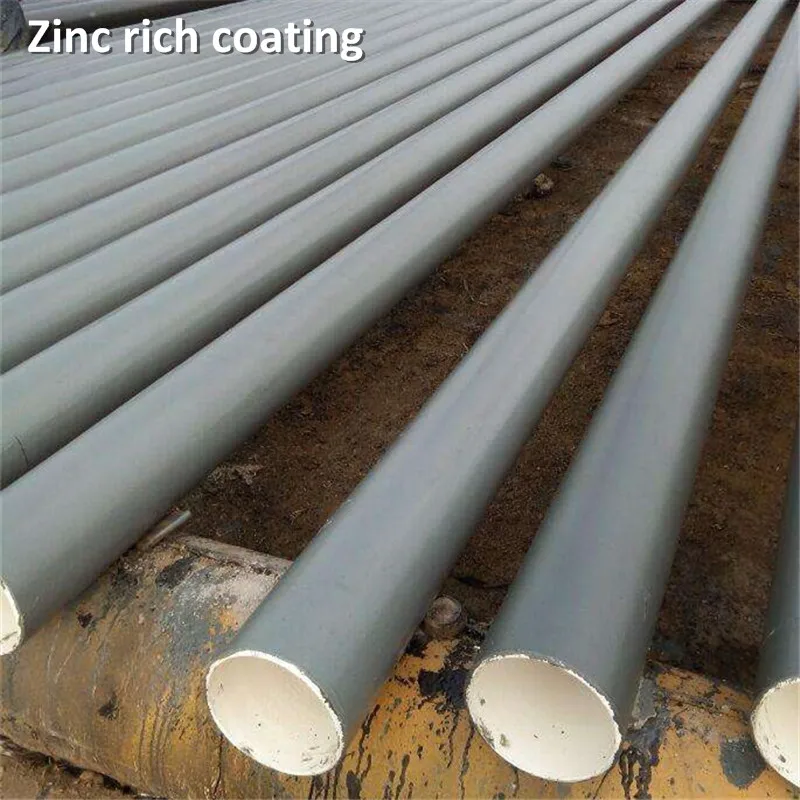

Inorganic zinc rich coatings generally consist of a silicate binder whereas organic zinc rich coatings can use a wide array of binders including epoxy polyurethane and alkyd etc.

Inorganic zinc silicate paint.

Inorganic zinc rich silicate protective coatings two component solvent based moisture cured inorganic zinc silicate coating product description general.

Silicate polymer network in an inorganic zinc silicate coating also provides a very effective barrier and silicate coatings without zinc can provide considerable durability even in quite corrosive environments 1.

As the name implies this type of coating contains large amounts of zinc metallic dust mixed with a zinc silicate binder and also contain high build polysiloxae or a hybrid topcoat and primer made from inorganic zinc.

The type of zinc rich coating is defined by the binder that is used during the formulation and manufacturing of the coating.

Volume of zinc corrosion products between the zinc and the coating.

Resist 86 is a two component moisture cured inorganic zinc ethyl silicate coating.

A zinc silicate coating is a type of coating that gives corrosion protection to surfaces such as steel.

So there are two mechanisms by which izs coatings provide protection to steel.

It is a fast curing very high zinc dust containing product.

Suitable for high speed welding and cutting with excellent resistance to damage caused by welding gas cutting and fairing.

Part of the interzinc 22 series of products a two component rapid recoat fast curing solvent based inorganic zinc rich ethyl silicate primer.

Conforms to sspc paint 20 level 2available in astm d520 type ii zinc dust version as standard.

Inorganic zinc rich silicate all surfaces to be coated should be clean dry and free from contamination.

It conforms to the compositional requirements of sspc paint 20 level 1 and the zinc pigments complies with astm d520 type ii zinc dust.

Inorganic zinc rich paint typically contains a binder like zinc silicate.

Oil or grease should be removed in accordance with sspc sp1 solvent cleaning.

Corrosion of steel is caused by water oxygen and ions present in abundance in our atmosphere diagrammatic representation of an inorganic zinc silicate coating on steel zinc corrosion products are trapped within the glassy matrix forming a layer that prevents further oxidation.

Prior to paint application all surfaces should be assessed and treated in accordance with iso 8504 2000.

On the other hand organic zinc rich paint makes use of urethane butyl or epoxy.

Surfaces must be dry clean and free from all contaminants ensure removal of dirt dust oil and all other contaminants that could interfere with adhesion of the coating.