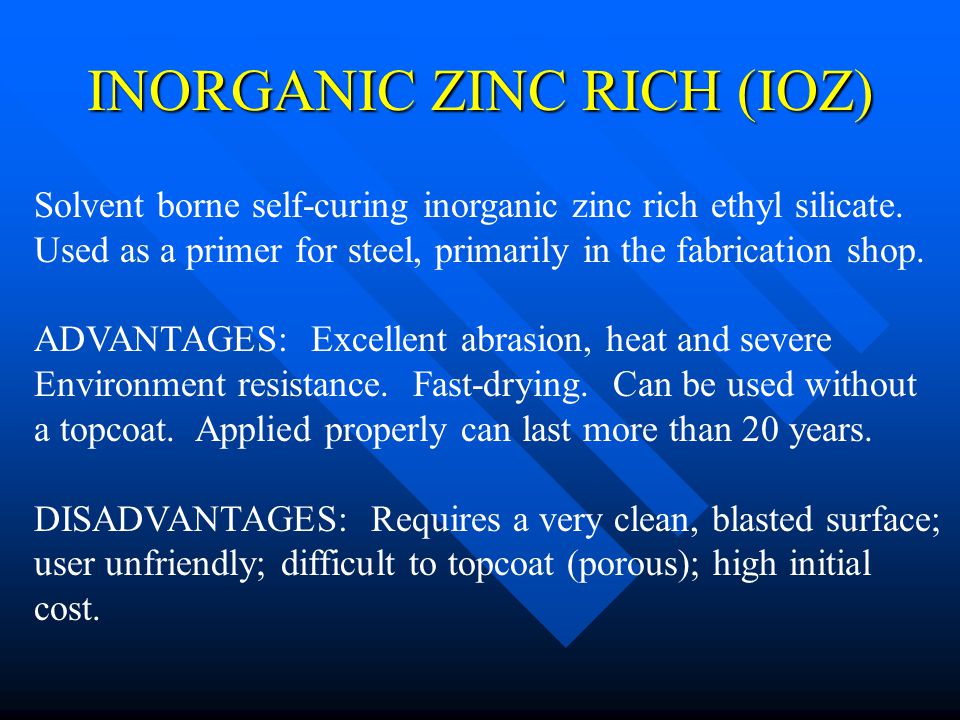

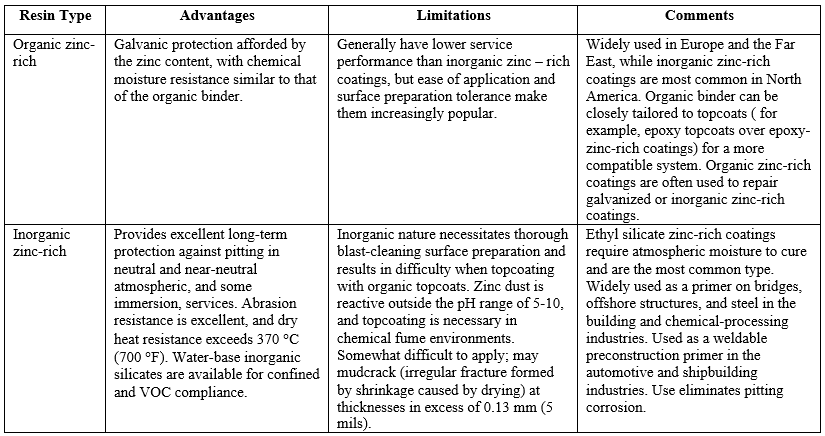

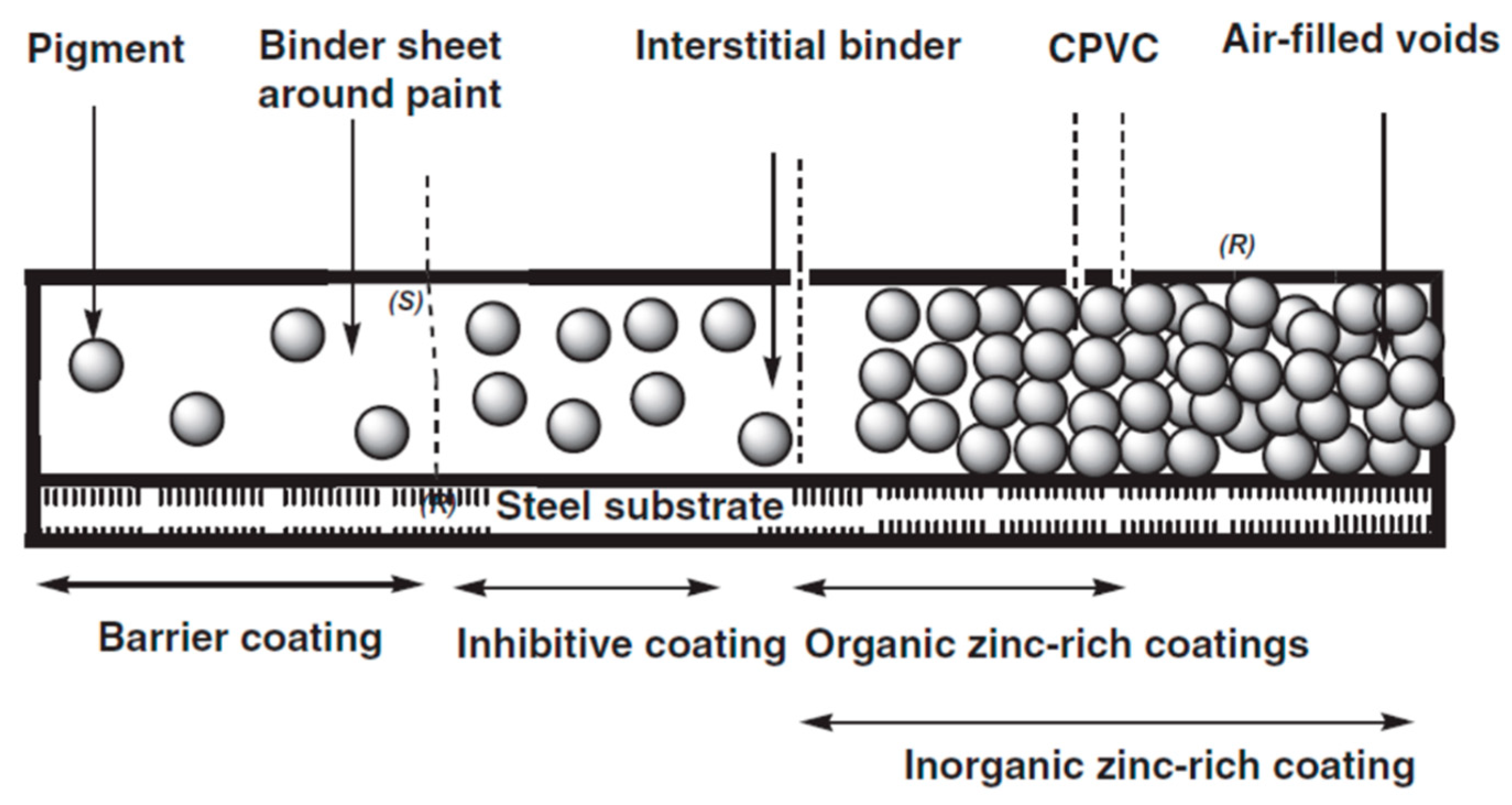

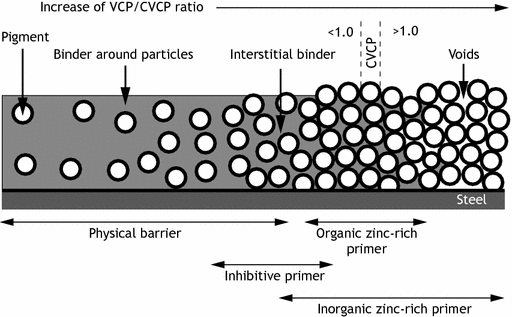

Inorganic zinc rich coatings generally consist of a silicate binder whereas organic zinc rich coatings can use a wide array of binders including epoxy polyurethane and alkyd etc.

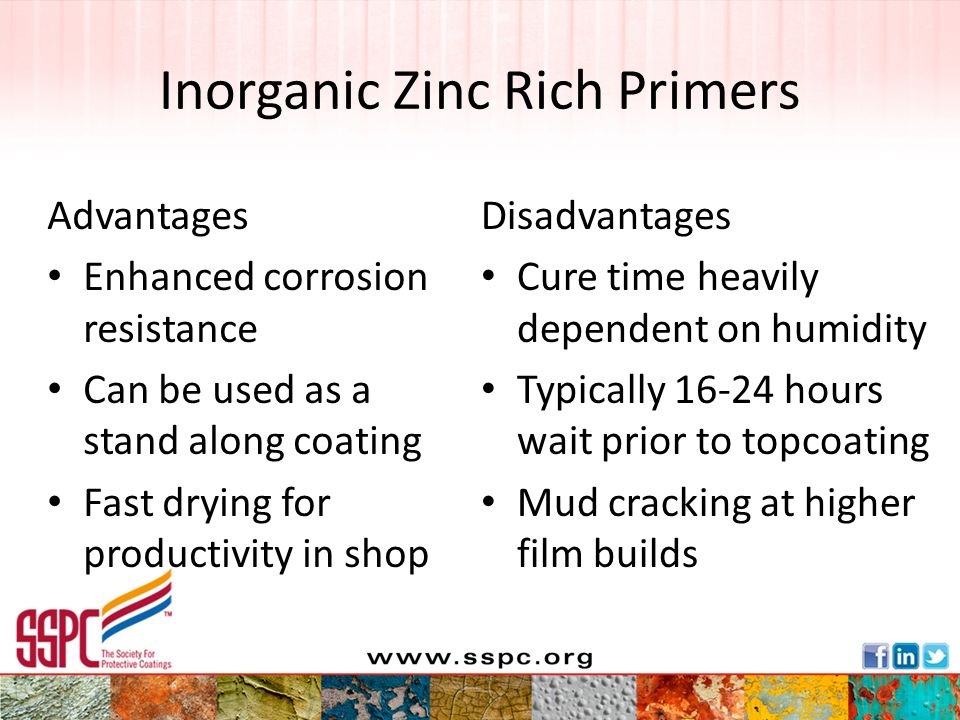

Inorganic zinc paint advantages.

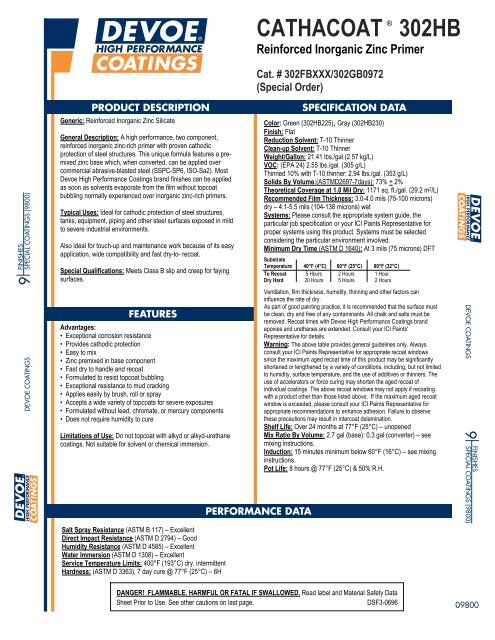

Part of the interzinc 22 series interzinc 2280 is a two component solvent based silicate inorganic zinc rich primer 80 suitable for use with a wide range of high performance anticorrosive systems and topcoats in both maintenance and new construction.

The type of zinc rich coating is defined by the binder that is used during the formulation and manufacturing of the coating.

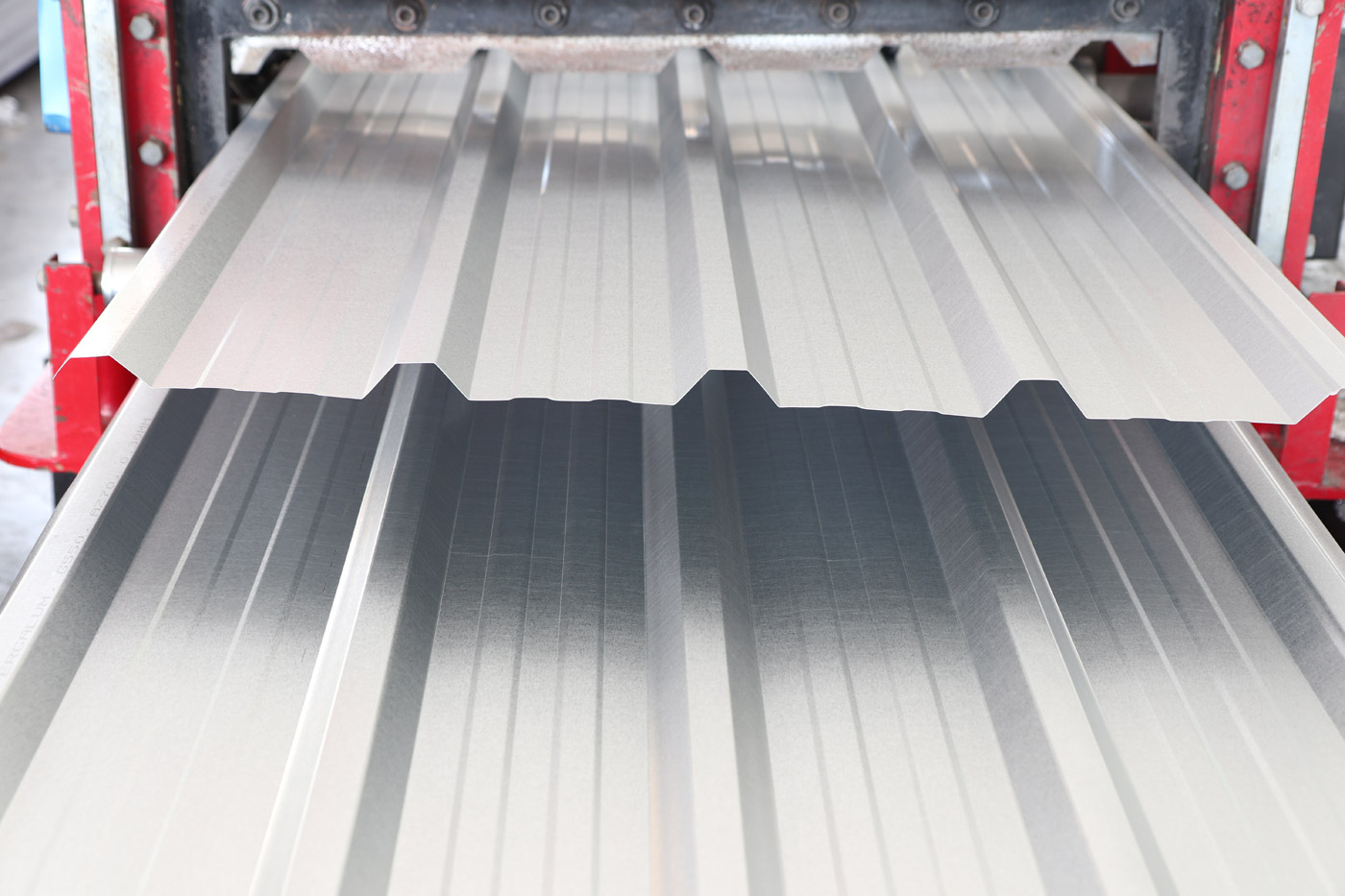

Industrial coating systems provide steel structures with long term protection against their environment.

Like all paint coatings zinc rich paint is a surface coating mechanically bonded to the steel at a few hundred pounds per square inch psi.

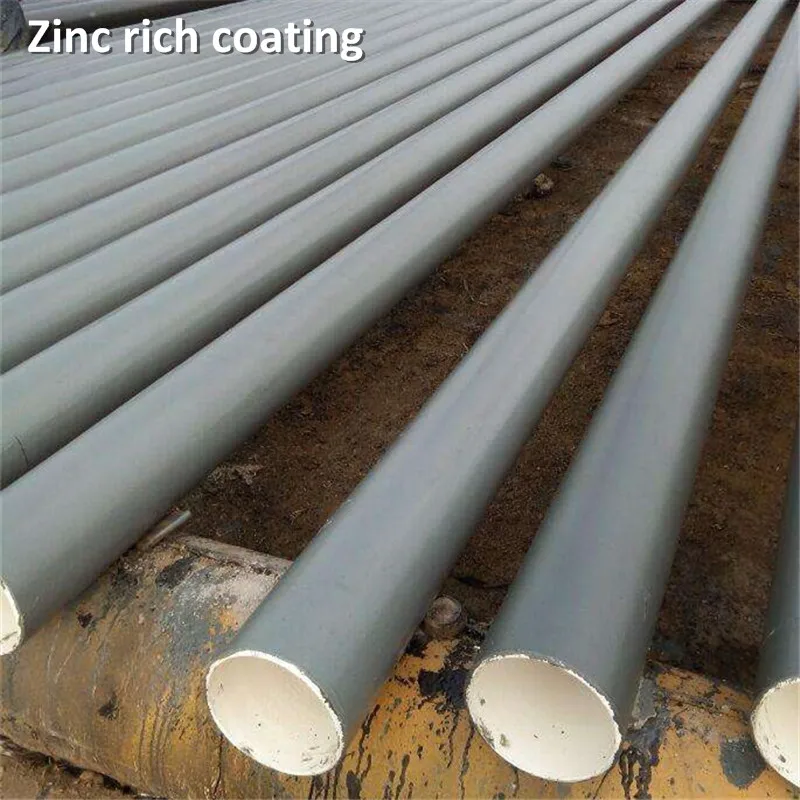

Inorganic zinc coating are used commonly for.

Or inorganic based on organic alkyl silicates.

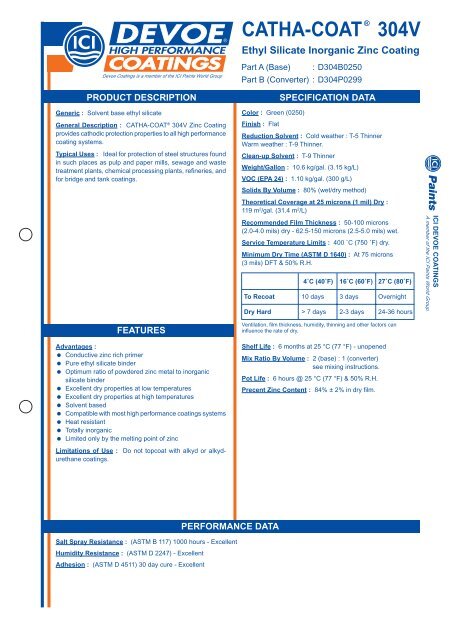

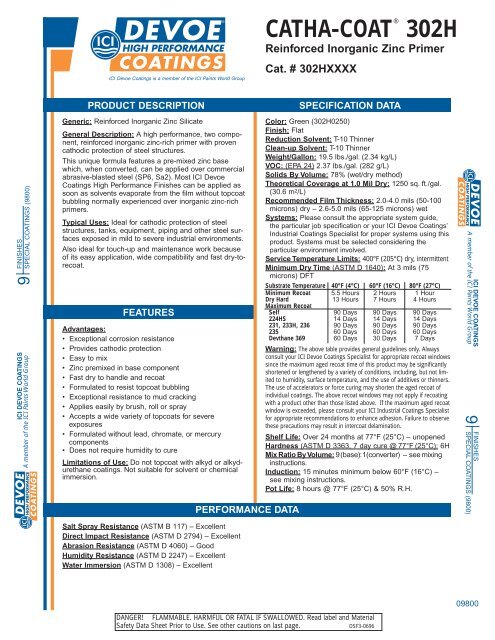

A three component solvent based inorganic ethyl silicate zinc rich coating.

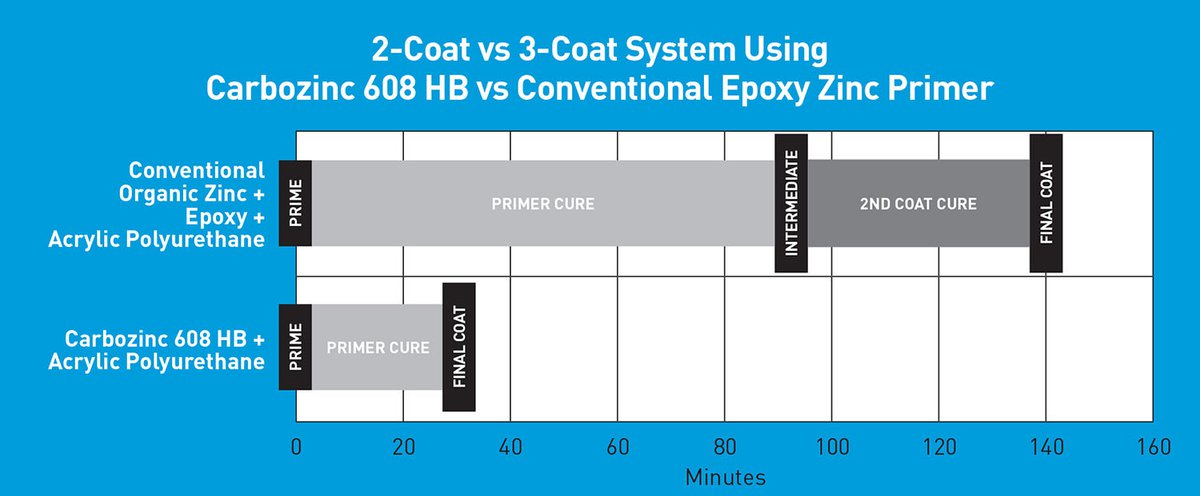

Selecting a coating system for your application.

Weighing price and performance.

Zinc clad ii plus is fast drying high solids low voc coating with 83 by weight of zinc dust in the dry film.

Inorganic zinc coating benefits.

Inorganic zinc coatings can cater to a wide range of applications.

Inorganic zinc rich coatings require an extremely clean surface prior to application.

They are commonly used in chemical plants refineries heavy equipment industry construction and engineering transportation industry energy services and military among others.