Attempts to formulate coatings using the ethyl silicate resin from inorganic zinc but without the added zinc were a complete failure.

Inorganic zinc coating under insulation.

That is primed with an inorganic zinc rich ioz coating.

The coatings on the market are engineered.

Shop primers and topcoats for inorganic zinc ioz minus 110 to 750 f minus 45 to 400 c novolac phenolic inorganic copolymer and inert polymeric matrix specifying and testing cui protective coating systems.

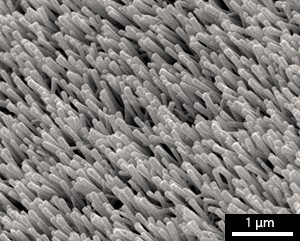

Corrosion under insulation is the name given to any type of corrosion galvanic acidic alkaline or chloride that occurs when moisture builds up on the external surface of insulated equipment such as pipework but also vessels and tanks.

Inorganic zinc rich coatings generally consist of a silicate binder whereas organic zinc rich coatings can use a wide array of binders including epoxy polyurethane and alkyd etc.

Using an inorganic zinc type primer works very well in this system as there is little sacrifice and it adheres well in high temperature environments or glass flake epoxy as the primer coating over carbon steel substrates can ensure a compatibility in most cases with thermal insulating coatings.

When determining the appropriate protective coating system to use under insulation is the expected service temperature of the equipment or piping especially when intermittent thermal cycling is present.

Vessel are coated with inorganic zinc to be insulated with 2 rockwool max temp 340 f produt type is hydrocarbon.

Since the year 2000 industrial practices or standards do not recommend using inorganic zinc rich coatings under thermal insulation.

The introduc tion of polysiloxane based elevated temperature coatings in the early 1990s allowed thick film build and temperature re.

Construction wants to apply additional 2 coats with epoxy to cover ioz.

Please give me your opinion can we use epoxy coating system with inorganic zinc primer under insulation.

What causes corrosion under insulation.

I think now you clear my query.

In it often a surprise that under insulation service is a more severe condition than straight atmospheric service.

In some applications inorganic zinc has worked well but not in others.

An inorganic zinc coatings is a type of coating that possess the distinct ability to give corrosion protection to surfaces such as steels.

As the name implies this type of coating has large amounts of zinc metallic dust mixed with a binder.

Special coating system must be utilized that have proven performance.

The water could be rain leakage sweating or another water source but the end result is the same the trapped.

Atmospheric under insulation ŧ.